Dispensing Valve is a key role in the aseptic filling line. How to ensure the dual guarantee of efficiency and sterility?

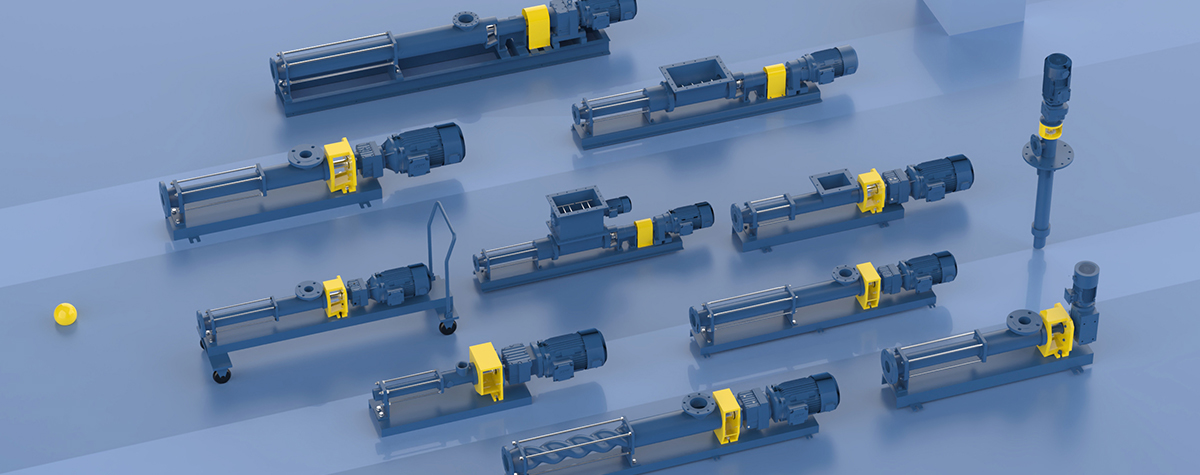

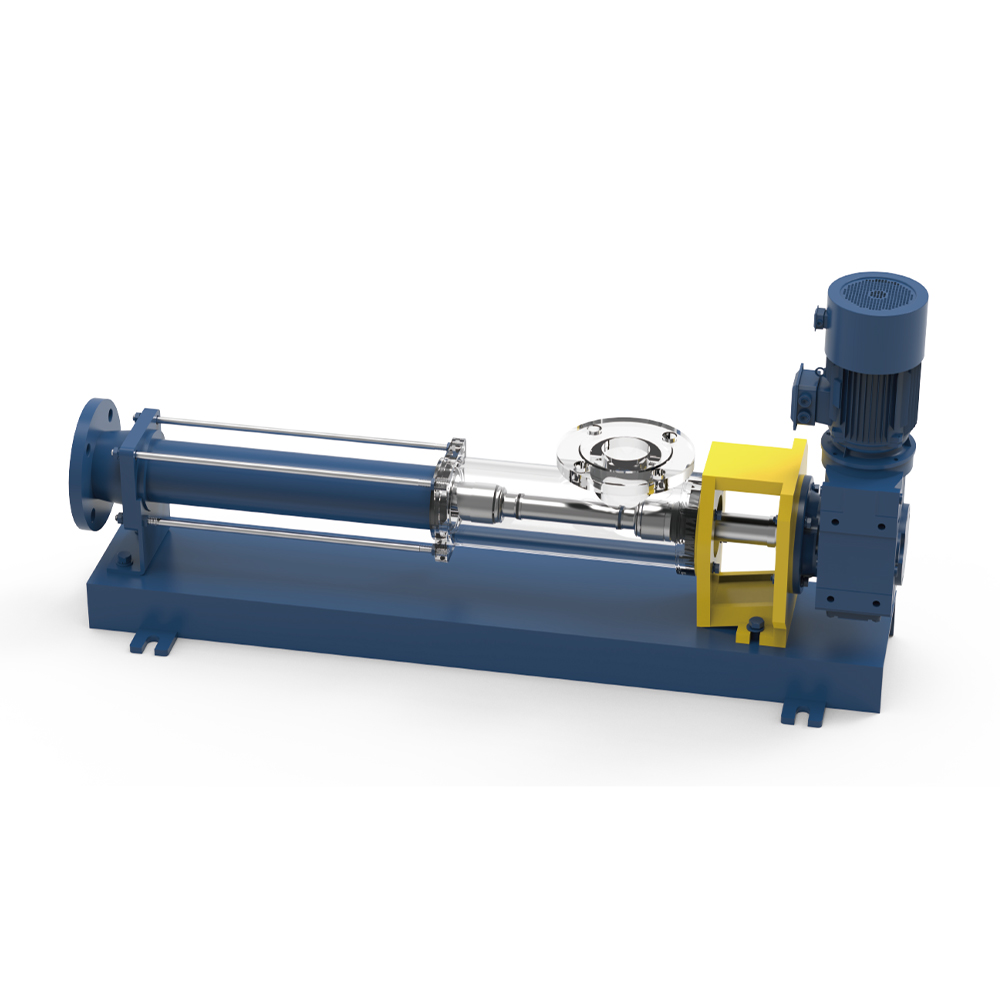

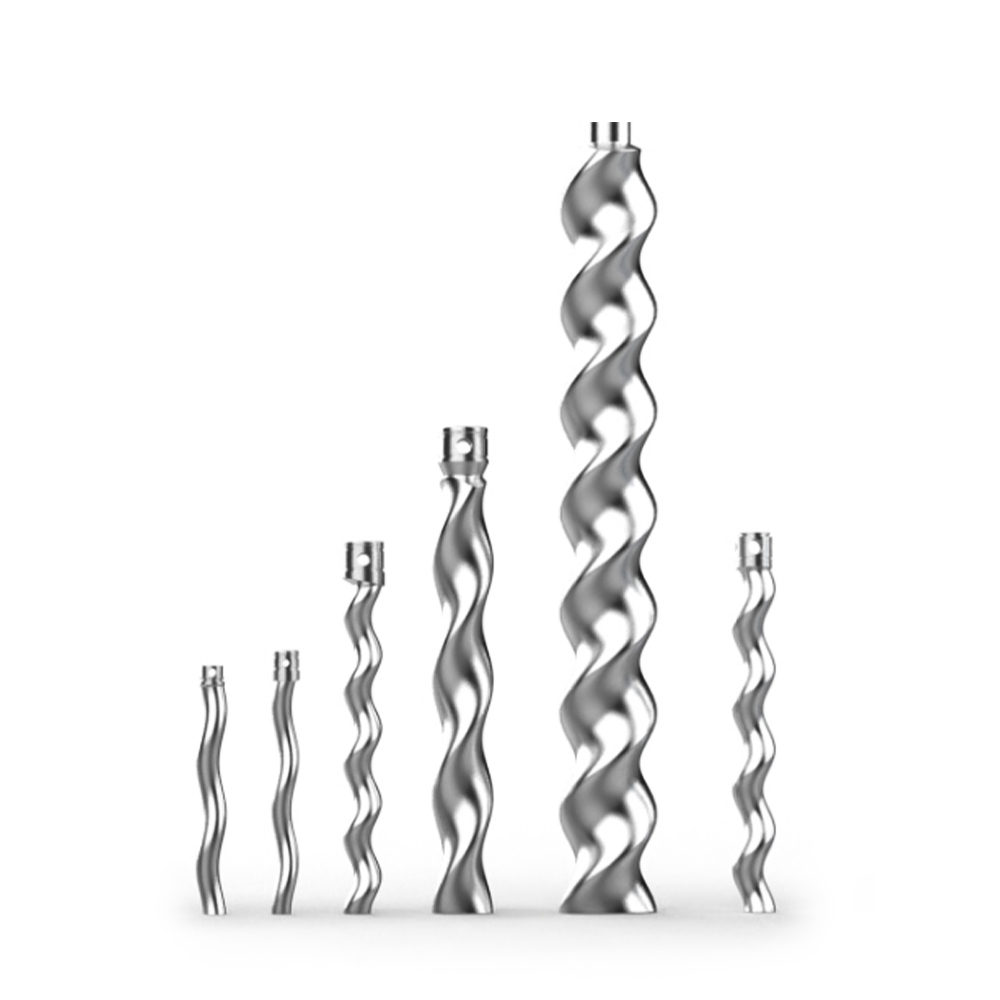

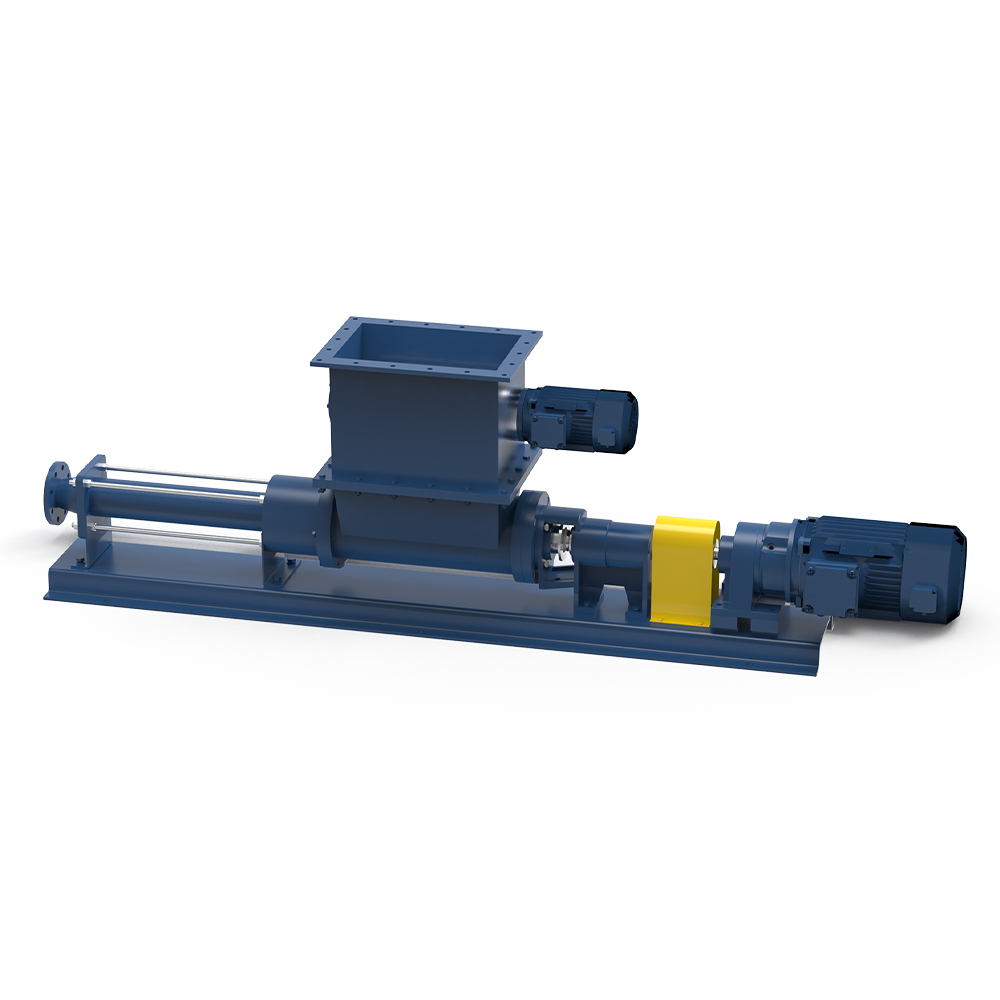

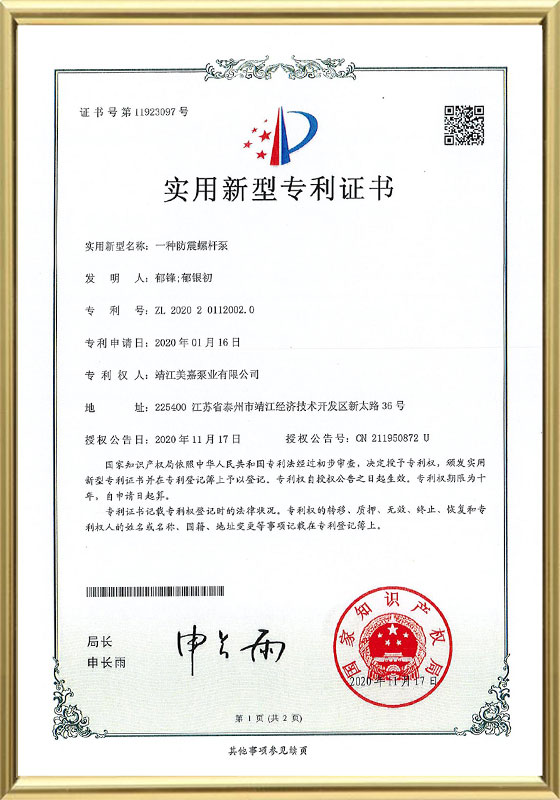

Jingjiang Meijia Pump Industry Co., Ltd. has a team of experienced, skilled and trustworthy engineers who embody professionalism and unremitting craftsmanship. Jingjiang Meijia Pump Industry Co., Ltd. has demonstrated their excellent expertise and unremitting pursuit of perfection from the initial stage of innovative concept design, to the complex and precise production process execution, to quality control measures, and finally to the assembly of a good pump system.

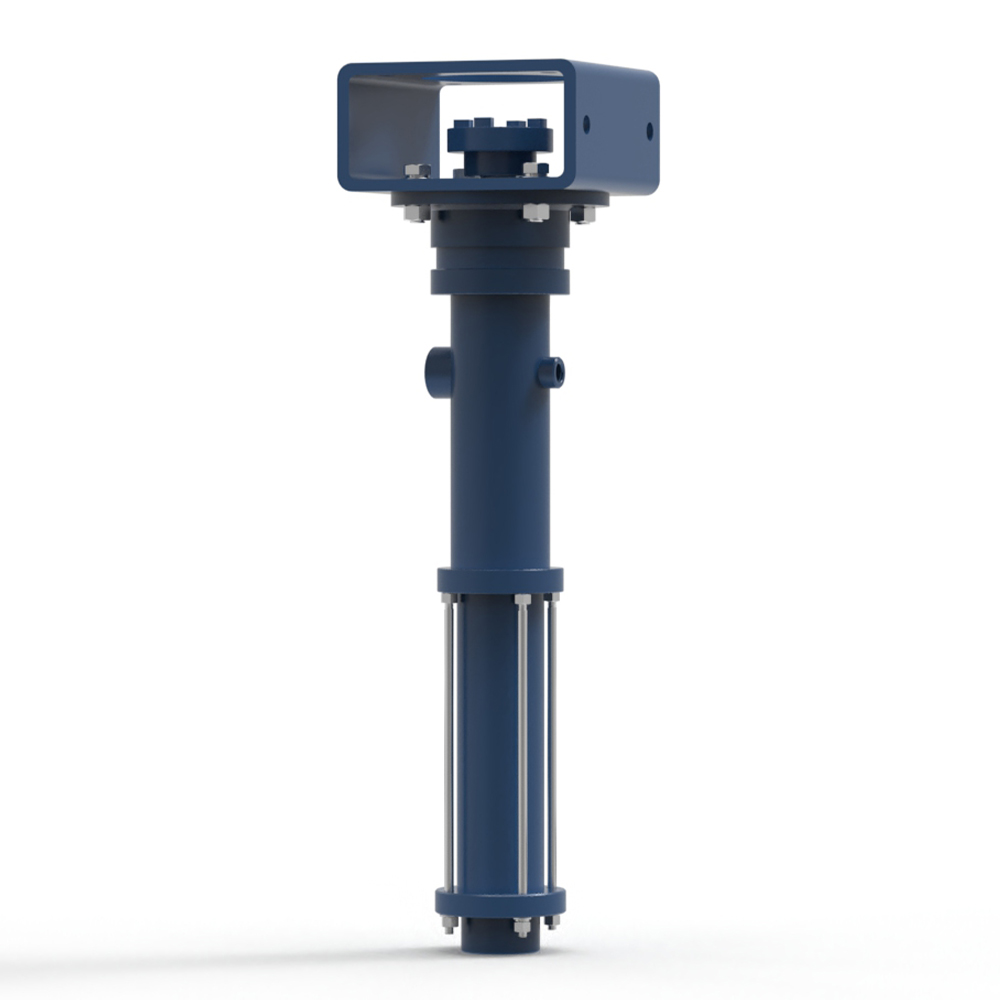

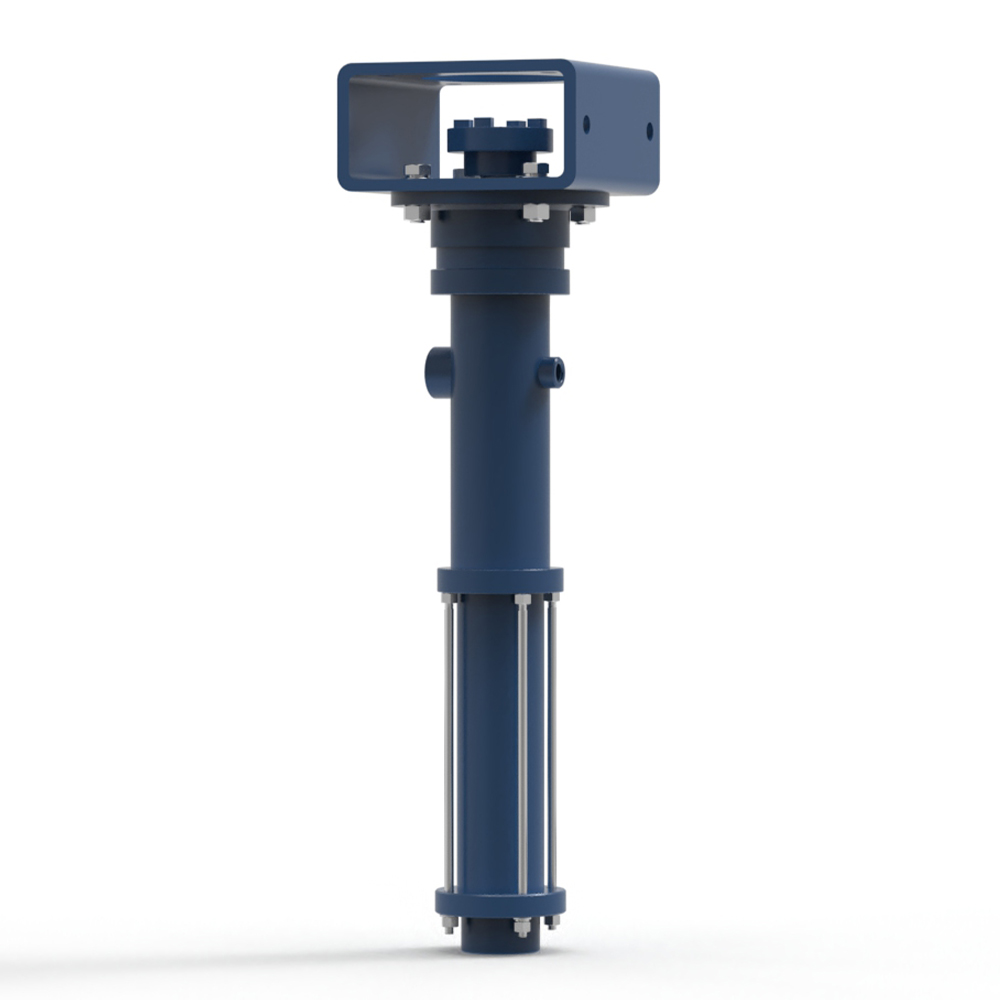

Dispensing Valve, as the heart of the aseptic filling system, is mainly responsible for accurately controlling and dispensing liquid products into various containers. It combines multiple features such as high-precision metering, fast response, stable operation, and easy cleaning and disinfection to ensure the accuracy and sterility of the filling process.

Equipped with advanced metering systems such as flow meters or weighing sensors, Dispensing Valve can accurately control the amount of liquid filled each time, meet product specification requirements, and ensure the stability of filling accuracy. The valve has the ability to open and close quickly, and can respond quickly after receiving the filling instruction, while maintaining a stable operating state, reducing the waiting time in the filling cycle and improving production efficiency. In order to meet the requirements of aseptic filling, the dispensing valve usually adopts a design that is easy to disassemble and reassemble, which is convenient for thorough cleaning and disinfection, prevents the growth of microorganisms, and ensures the sterility of the product.

The dispensing valve effectively blocks the invasion of external microorganisms and ensures the sterility of the filling environment through its excellent sealing performance and rapid cleaning and disinfection capabilities. This is especially important for products that require highly clean and aseptic conditions, such as medicines and dairy products; the combination of automated operation and rapid response capabilities enables the dispensing valve to significantly improve filling efficiency. By working in conjunction with automated equipment such as filling robots and conveyor belts, the continuity and stability of the filling process are achieved, labor costs are reduced, and production efficiency is improved; the precise metering system and stable operating state ensure that the amount of liquid filled each time reaches the predetermined value, and there is no leakage or pollution during the filling process, thereby ensuring the quality and safety of the product. At the same time, aseptic filling can also help extend the shelf life of products and maintain the taste, color and flavor of products.

With the continuous development of industries such as pharmaceuticals, food and cosmetics, the requirements for aseptic filling technology are getting higher and higher. As a key component of the aseptic filling line, the future development of Dispensing Valve will show the following trends:

With the continuous advancement of technology, the metering accuracy of Dispensing Valve will be further improved, and more intelligent elements will be incorporated, such as automatic adjustment of filling parameters, real-time monitoring of filling status, etc., to meet more complex and sophisticated filling needs; in order to meet the filling needs of different industries and different products, Dispensing Valve will continue to launch more diverse models and specifications, as well as stronger liquid compatibility, to ensure stable operation under various working conditions; in order to further improve the production efficiency and product quality of aseptic filling lines, the cleaning and disinfection technology of Dispensing Valve will also continue to innovate and improve to achieve a faster, more thorough and environmentally friendly cleaning and disinfection process.